Resources

Expert Insights and Information

As a member of the medical device community, you need access to expert resources and industry knowledge to make critical decisions for your products and patients. We are here to share our expertise and help solve your most complex medical device manufacturing challenges.

Case Studies & Whitepapers

Reducing Risk with Vertical Integration

A success story demonstrating how our businesses work together to produce technically-challenging, precision components and devices for our customers.

Minimize Your Profile and Maximize Your Pull Strength

A variety of design variables can impact the overall profile and strength of your pull wire system. We’ll help you better understand your options, so you can make informed decisions for your project.

Development and Distribution of a Finished Medical Device

In this success story, we demonstrate how JunoPacific has partnered and grown with our customer from the design and development phases of their device to the high-volume production they maintain today.

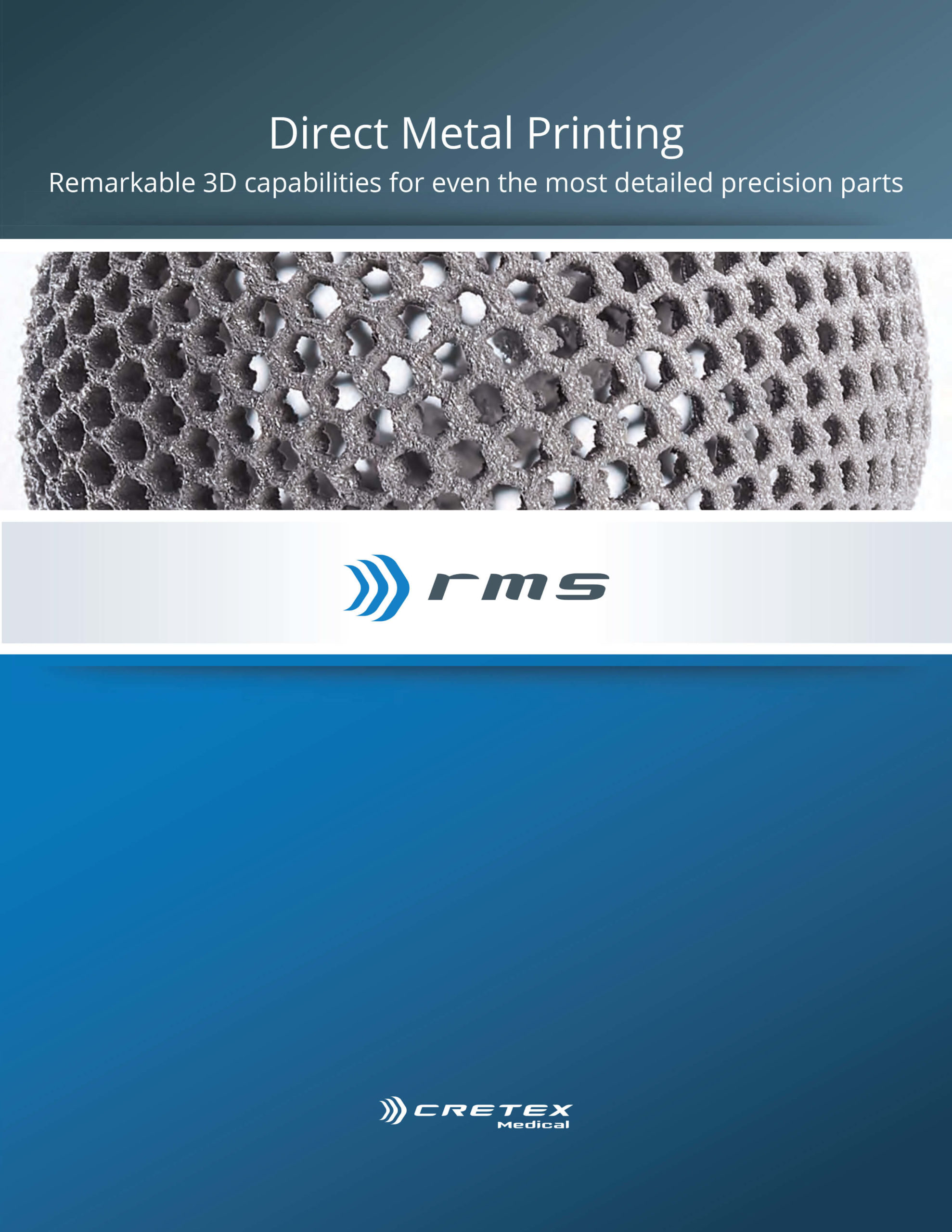

Design for Additive Manufacturing

To realize the full benefits of additive manufacturing during all phases of production, it is important to incorporate design for additive manufacturing (DFAM) early in the design process. Optimize your design and manufacturing processes with these tips.

Featured Articles

Cretex Medical | CDT Brooklyn Park Teams Raise $6,950 for Local Charities

At Cretex Medical, giving back is a team effort, and our Brooklyn Park employees took that spirit to the next level this April during our Spring Basket Display Fundraiser. Through creativity, collaboration, and community support, teams assembled themed baskets filled with donated goodies, raffled them off, and raised an impressive $6,950 for charity!

Design for Orthopedic Instrumentation

The machining sector in the orthopedic device industry is highly specialized, especially for the production of precise technologies such as orthopedic drills, guidewires, and fixation pins. The demand for high-quality, high-precision parts continues to grow as medical devices become more intricate and patient-specific. With minimally invasive surgical procedures increasing in popularity for an ever-growing range of applications, the ergonomics and design of instruments play a crucial role in enhancing surgical techniques. Well-designed instruments improve precision in the operating room (OR), as well as operating efficiency and enhanced patient outcomes.

Cretex Medical | rms Volunteers at The Dwelling Place for Domestic Violence Awareness Month

October is Domestic Violence Awareness Month - a time to shine a light on the struggles faced by survivors of domestic violence and to show support through active involvement. At Cretex Medical | rms, we value the importance of contributing to our community and supporting meaningful causes. This month, rms employees volunteered at The Dwelling Place, a local organization offering safe transitional housing and supportive services for women and children escaping domestic abuse.

Additive Manufacturing: Moving Beyond Implants - An Orthopedic Innovators Q&A

As more orthopedic device manufacturers exhibit interest in Additive Manufacturing (AM) for even more products, the challenges increase further. Aspects such as scalability come into play, as well as the need to affordably produce an array of technologies with these machines. As a result, companies are seeking experienced suppliers who maintain expertise with AM for orthopedic implants, instruments, and other devices.

Fortunately, Troy Olson, Director of Additive Operations at Cretex Medical | rms, has offered insights on a variety of inquiries surrounding this topic in the following Q&A. He provides clarification on what medical device firms need to keep in mind when working with a supplier on additively manufactured products, the benefits of working with an experienced partner, and some often overlooked factors.

Cretex Medical | rms Spreads Warmth with Blanket Donations

At Cretex Medical | rms, giving back to the community is woven into our fabric. Our amazing team at the Anoka and Coon Rapids locations recently came together for a heartwarming evening of blanket-making and card-crafting, all with the mission of bringing comfort and joy to the elderly in our community.

Cretex Medical Shows Continuous Support by Participating in Thumbs Up’s 11th Annual 5K & 10K Run/Walk/Bike

On September 21, 2024, Cretex Medical proudly participated in Thumbs Up’s 11th Annual 5K & 10K Run/Walk/Bike event. This highly anticipated event, held in Elk River, MN, brought together participants of all ages for a day of community engagement, fitness, and support for mental health awareness.

As a long-time supporter of Thumbs Up, a nonprofit organization dedicated to mental health advocacy, Cretex Medical not only showed up with a strong team of employees but also made a significant financial donation. This commitment is a reflection of our values and dedication to giving back to the communities where we live and work.

Corporate Social Responsibility at Cretex Companies

Corporate Social Responsibility (CSR) reports are becoming an essential way for companies to communicate their values, achievements, and goals with various stakeholders. At Cretex Companies, our CSR is built on five pillars that define who we are and guide how we operate every day: Our People, Our Culture, Our Customers, Our Environment, and Our Governance. When you view or download our CSR report, you’ll see how our accomplishments across these pillars demonstrate our strengths and prepare us for future successes.

Medical Device Machinists Are Multi-Task Masters

Medtech machining equipment has evolved to meet customers’ demands for micro components, material variability, more complex shapes, and tighter tolerances.

Cretex Medical | rms's Pacing Operations Manager was featured in MPO Magazine.

Women in MedTech: Rona Gungon, Product Development Engineering Supervisor at Cretex Medical

Rona Gungon, Product Development Engineering Supervisor at Cretex Medical | QTS, was featured in Medical Design & Outsourcing Magazine for their Women in MedTech series.

Rona’s career in the medical device packaging sector has been marked by a series of progressive roles, including Quality Assurance, Customer Quality Liaison, and Project Engineering. Her experience and insightful understanding of the industry’s complexities enable her to now lead a team of Product Development engineers.

Company Information

Cretex Companies 2024 Corporate Social Responsibility Report

The five pillars of our corporate social responsibility are Our People, Our Culture, Our Customers, Our Environment and Our Governance. They express who we are and guide how we do business every day.Brochures

Medical Device Design, Molding & Assembly

Cretex Medical | CDT (JunoPacific)

Precision Metal Stamping Solutions

Cretex Medical | CDT (Meier)

Medical Device Assembly & Packaging

Cretex Medical | QTS

Precision-Machined Medical Implants & Components

Cretex Medical | rms

Direct Metal Printing

Cretex Medical | rms

Orthopaedic Solutions

Cretex Medical | rms

Laser Processing

Cretex Medical | CDT (Spectralytics)